Understanding DC and AC Fan Operation for Optimal Radiator Cooling

DC Fan Operation Principle

DC fans operate using a direct current power source. When current passes through a conductor, it creates a magnetic field around it. Consequently, this magnetic field interacts with a fixed external magnetic field, causing movement due to attraction and repulsion. In DC fans, silicon steel sheets generate magnetic poles that interact with rubber magnets, thereby making the fan blades rotate. Additionally, a Hall sensor provides synchronization signals, ensuring the fan blades continue to move smoothly. Importantly, the fan’s direction follows Fleming’s right-hand rule. As a result, this type of fan commonly serves in computer radiators to manage heat dissipation efficiently.

AC Fan Operation Principle

In contrast, AC fans use an alternating current (AC) power supply, where the voltage alternates between positive and negative. This requirement necessitates circuit control to alternate the activation of two sets of coils, which creates varying magnetic fields. Notably, the frequency of the AC power supply affects the speed at which the magnetic poles switch. Specifically, higher frequencies result in faster switching and potentially higher fan speeds; however, excessively high frequencies can hinder operation. Unlike DC fans, AC fans rely on this alternating current process for effective function. Therefore, choosing between AC and DC fans significantly impacts the cooling performance of a radiator based on specific cooling requirements.

Key Factors in Fan Performance

Firstly, air volume and pressure play critical roles in determining a fan’s efficiency in cooling a radiator. This efficiency depends on the fan’s ability to move air, which we measure in cubic feet per minute (CFM) or cubic meters per minute (CMM). For instance, a 50x50x10mm CPU fan typically provides around 10 CFM, while a 60x60x25mm fan offers 20-30 CFM. Thus, a higher air volume improves heat dissipation, but maintaining a balance between air volume and pressure proves crucial. Specifically, high air volume with low pressure may fail to reach the radiator effectively, while high pressure with low volume can reduce cooling efficiency. Consequently, selecting the right fan involves matching these characteristics to the radiator’s design, such as fin material and density.

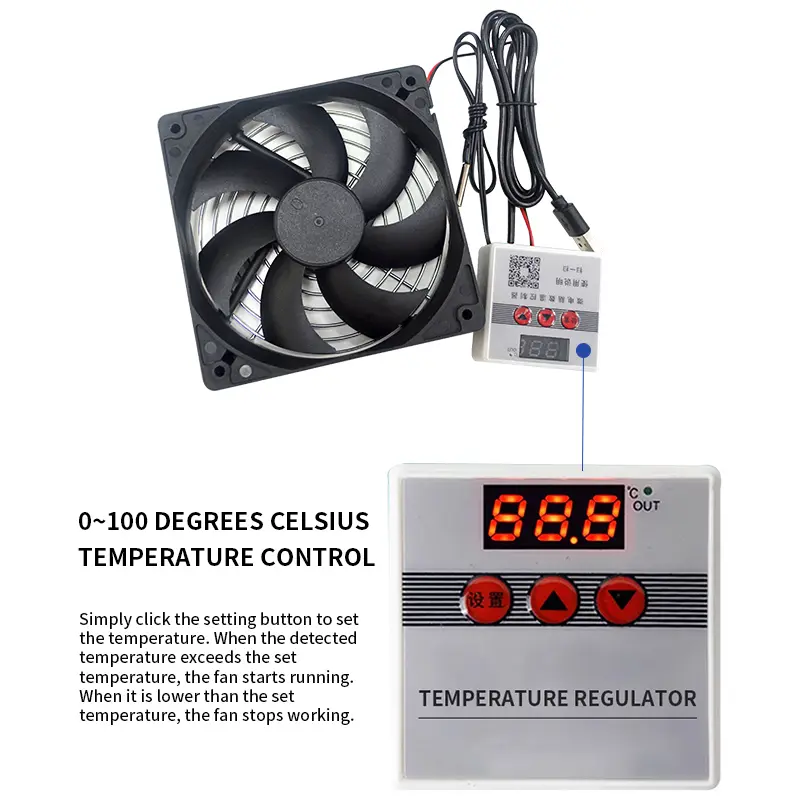

Secondly, fan speed and control, measured in RPM (revolutions per minute), influence factors like motor coil turns, voltage, and blade design. Moreover, users can adjust fan speeds manually or automatically based on temperature. In automatic systems, temperature sensors optimize fan speed, balancing noise levels and cooling performance. On the other hand, manual controls allow users to adjust speeds according to seasonal needs, such as lower speeds in winter for reduced noise and higher speeds in summer for improved cooling.